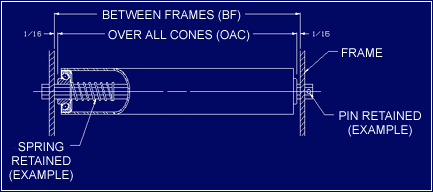

Rollers are an assembly of three major components: axle, tube, and bearings. The length of a roller is defined in terms of the “between frame width (Click here for drawing)” or “BF”. This “BF” dimension allows 1/16″ clearance between the extension on the bearing and the side frame. Remember, Northwest Conveyor can provide your rollers to nearly any “BF” dimension, so you are not limited in your product selection. Frame thickness is also important information to insure proper assembly (with pin retained and re-greasable rollers). The rollers can be provided with special coatings like urethane and zinc plating upon request. To begin quoting a roller, your salesperson will need to know the following information; between frame dimension, axle size, tube size, and any sprocket or grooving dimensions.

The between frame dimension, or “BF”, refers to the width between frames that the roller needs to fit into. The rollers are built to a BF-1/8″ dimension, to allow 1/16″ of space between the cone of the bearing and the frame rails on both sides. This is to allow sufficient clearance for the rollers to spin freely without undue friction.

Gravity Rollers are the means by which products are transported in many types of gravity conveyor systems. They are available in sizes from 1″ Dia. x 16 ga with a 1/4″ round axle up to an 8″ Dia. x 1″ wall with a 3-7/16″ round axle. Hex axle sizes available from 5/16″ – 1-1/16″. Numerous bearing

Gravity Rollers are the means by which products are transported in many types of gravity conveyor systems. They are available in sizes from 1″ Dia. x 16 ga with a 1/4″ round axle up to an 8″ Dia. x 1″ wall with a 3-7/16″ round axle. Hex axle sizes available from 5/16″ – 1-1/16″. Numerous bearing

options are available as well as special XXXXXX

Power Rollers with Sprockets are the means by which products are transported in many types of heavy duty powered unit handling conveyor systems. These rollers use type “A” plate sprockets welded to tubes for use in chain drive live roller conveyor. Single or multiple sprockets per roller are available. They are available in sizes from 1.9″ Dia. x .145 wall with a 7/16″ hex axle up to a 5″ Dia. x 3/4″ wall with a 1-7/16″ round axle. Hex axle sizes available from 7/16″ – 1-1/16″. Numerous bearing options are available. Location of sprockets, chain size and number of teeth must be specified. Hardened tooth sprockets are also available.

Power Rollers with Sprockets are the means by which products are transported in many types of heavy duty powered unit handling conveyor systems. These rollers use type “A” plate sprockets welded to tubes for use in chain drive live roller conveyor. Single or multiple sprockets per roller are available. They are available in sizes from 1.9″ Dia. x .145 wall with a 7/16″ hex axle up to a 5″ Dia. x 3/4″ wall with a 1-7/16″ round axle. Hex axle sizes available from 7/16″ – 1-1/16″. Numerous bearing options are available. Location of sprockets, chain size and number of teeth must be specified. Hardened tooth sprockets are also available.

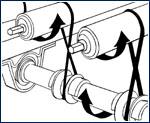

Lineshaft Rollers are provided with one, two, or three grooves rolled into the tube to accommodate 3/16″ diameter urethane belts. Location of grooves must be specified. Standard roller diameters include 1-3/8″, 1.9″ and 2-1/2″. Other sizes are available.

Lineshaft Rollers are provided with one, two, or three grooves rolled into the tube to accommodate 3/16″ diameter urethane belts. Location of grooves must be specified. Standard roller diameters include 1-3/8″, 1.9″ and 2-1/2″. Other sizes are available.

Bearings can be divided into four groups: Non-precision, semi- precision, precision, and journal bearings.

Bearings can be divided into four groups: Non-precision, semi- precision, precision, and journal bearings.

Non-Precision Bearings have hardened steel balls and raceways. They are often referred to as “full compliment” meaning they do not have a ball retainer. The outer race is either stamped or machined. Non-precision bearings are used where speeds and loads are moderate.

Semi-Precision Bearings have hardened steel balls and raceways along with a ball retainer of “cage” to separate the balls. These bearings are suitable for speeds up to 400 rpm.

Precision Bearings have hardened and ground balls, raceways and ball retainers. They are normally shielded and sealed. Precision bearings are suitable for speeds above 400 rpm and for heavier loads.

Journal Bearings consist of a housing and a bushing. They have no balls or seals. The housing is generally plastic or wood. Journal bearings are used in wash-down or similar conditions.

Roller Capacities

Roller capacity refers to the maximum load a single roller can support. Key factors in establishing a rollers capacity are as follows;

– Bearing Capacity

– Bearing offset (distance from side frame to centerline of balls)

– Axle deflection

– Tube deflection

Capacities of the rollers are based on tube deflection of no more that .21% of BF and axle angular deflection of no more that 1° at the bearings. Angular deflection of axle at the bearings is limited to .75° for cylindrical semi-precision and precision bearings.

Because the conveying surface of products is not perfectly flat, use only 2/3 of the rollers under the product when calculating the required roll capacity.

Common sense tells you that it is not practical to use 1-3/8″ diameter roller on 1-1/2″ centers for a 6000 lb. product (12″ x 120″ long), so in addition to the rule above, use the following guide lines:

Conveyor Roller Capacities

| Roller Diameter & Axle | Maximum Product Weight |

|---|---|

| 1" Dia - 5/16" hex | 300 lbs. or 136 kg |

| 1-3/8" Dia - 5/16" hex | 600 lbs. or 272 kg |

| 1.9" Dia - 7/16" hex | 1500 lbs. or 680 kg |

| 2-1/2" Dia - 11/16" hex | 3500 lbs. or 1588 kg |

| 3-1/2" Dia - 1-1/16" hex | 6000 lbs. or 2722 kg |

| 3-1/2" Dia - 1-7/16" round | 10,000 lbs. or 4536 kg |

| 4" Dia - 1-7/16" round | 15,000 lbs. or 6804 kg |

| 5" Dia - 1-11/16" round | 25,000 lbs. or 11340 kg |

| The above guidelines assume zero shock load and are not applicable for three or more lanes. |