Supports

Available in pipe and yoke support base style, or angle “H” style support. Both styles are available in painted mild steel or stainless steel.

Available in pipe and yoke support base style, or angle “H” style support. Both styles are available in painted mild steel or stainless steel.

Motors/Reducers

- 230/460/60/3 56-C

- 110/60/1 56-C

- 90 Volt DC motor with Nema 4/12 Controller (for 120V AC input)

- 180 Volt DC motor with Nema 4/12 Controller (for 240 AC input)

Fixed Speed Motor Reducers:

- Available in 30, 60, 90, 120, 150 FPM

- Available in 1/2, 3/4, 1 and 1 1/2 Horse Power

Variable AC Inverters

- Available in Nema 1 and Nema 4.

Chains

Available in straight running and side flexing plastic and steel.

Copes

A cope is used when the elevation of the conveyor needs to be changed. When a cope is required, special consideration should be given to the type of chain used, product slippage and product tippage. Most products are able to handle 3/4” per foot maximum incline or decline.

Component Specifications:

- Adjustable + or – 3/4” per foot

- 5 1/2” deep frame

- Chain required is 2’ – 0”

- Incline copes require tab style chain

Accessories

Motor Mounts – Above or below mount angle iron in painted mild steel or stainless steel

Combiners

A combiner takes mass flow round products and combines them into single file. It is used when there is accumulation or when product is being transported in mass. By setting the chains at various speeds, product can be single filed without jamming and a constant rate of product can be maintained to be fed into other machinery.

A combiner takes mass flow round products and combines them into single file. It is used when there is accumulation or when product is being transported in mass. By setting the chains at various speeds, product can be single filed without jamming and a constant rate of product can be maintained to be fed into other machinery.

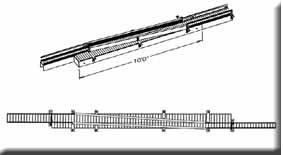

Component Specifications:

- Roller combiner rails

- 10’-0” O.A.L.

- 8” deep frame